Improve inventory planning and prevent stockouts in Q1 2026 with expert insights from Corless Logistics Group. Strengthen your supply chain today.

As Australian businesses prepare for the year ahead, Q1 2026 is shaping up to be a critical period for inventory planning. Seasonal shifts, fluctuating demand following the holiday trading period, and ongoing supply-chain volatility make stock availability more challenging to control. Without a structured and proactive approach, organisations risk losing sales, reducing customer satisfaction, and increasing operational pressure during an already competitive quarter.

What Is Inventory Planning & Why It Matters

Inventory planning is the strategic process of determining the optimal quantity, timing, and distribution of stock to meet customer demand while managing costs. It aligns forecasting, procurement, warehousing, and distribution to ensure products are available when and where they are needed. In Australia’s demanding logistics environment, businesses that refine this process benefit from fewer stockouts, stronger cash flow, and improved supply-chain reliability.

Common Causes of Stockouts in Q1 (and beyond)

Stockouts occur when demand exceeds available supply, and they are particularly disruptive in the first quarter of the year when consumer behaviour can shift rapidly after peak-season trading. Several recurring issues increase the likelihood of shortages:

• Inaccurate demand forecasting, such as failing to adjust for the holiday season, promotions, or shifting consumer trends.

• Supply-chain disruption: shipping delays, supplier lead-time variability, and logistics bottlenecks.

• Poor inventory visibility or manual tracking leads to under-ordering or delayed restocks.

• Lack of buffer or safety stock, leaving no cushion for an unexpected surge in demand or delay in supply.

Key Elements of Smart Inventory Planning to Prevent Stockouts

Smart stock management relies on a combination of forecasting accuracy, operational agility, and real-time visibility. The following elements underpin a modern and effective strategy.

• Demand Forecasting & Data-Driven Insights – A strong forecasting method uses historical data, seasonal trends, promotional plans, and market insights to project demand, helping businesses anticipate peak periods, reduce uncertainty, and allocate resources more effectively.

• Safety Stock / Buffer Stock Strategy – Maintaining an appropriate level of buffer stock protects businesses from supply delays or demand surges while ensuring product availability without tying up excessive working capital or warehouse capacity.

• Inventory Segmentation (e.g. ABC-Type Approach) – Segmenting products into priority groups helps identify which items require stricter monitoring, faster replenishment, and higher service-level focus, ensuring high-value and fast-moving items receive the most attention.

• Strategic Stock Allocation & Multi-Location Distribution – Optimising stock placement across multiple warehouses or distribution centres reduces regional shortages and improves delivery efficiency by positioning inventory closer to customer hubs and allocating it based on demand trends.

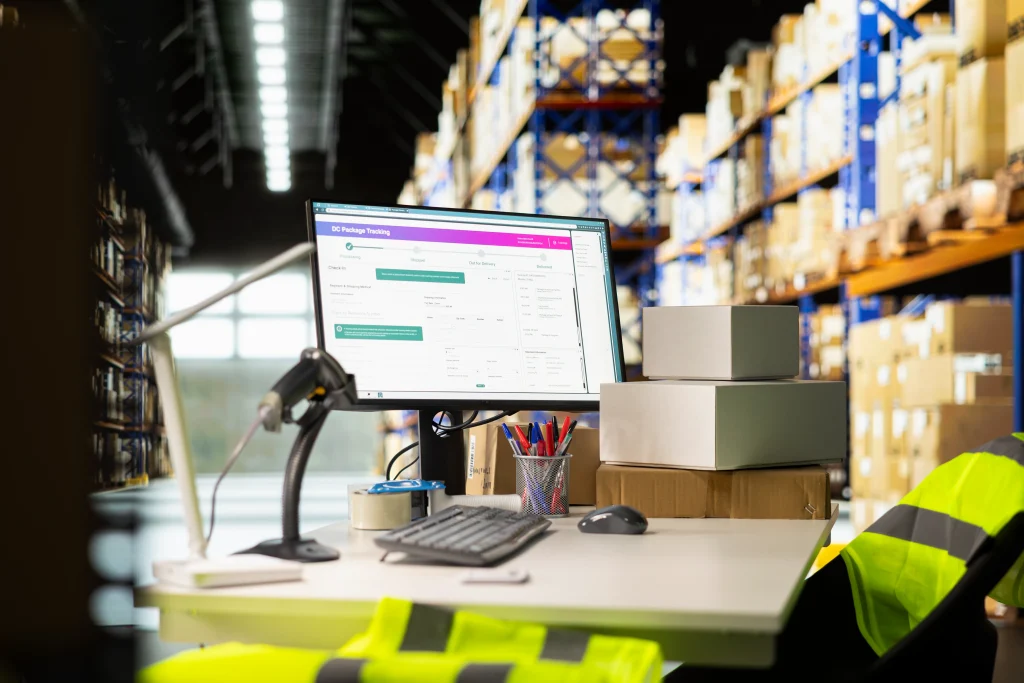

• Use of Technology & Integrated Inventory Systems – Modern inventory systems provide real-time tracking, automated alerts, and clear reporting, while integrated platforms improve coordination across suppliers, warehouses, and transport partners to reduce oversight and speed up decision-making.

• Set Clear Inventory Policies and Service-Level Targets – Formalised policies such as reorder points, review cycles, buffer thresholds, and service-level commitments establish consistency and accountability, and when paired with measurable KPIs, form the foundation of a reliable stock management process.

Strengthening Q1 Outcomes with Corless Logistics Group

Effective inventory planning is essential for preventing stockouts, improving operational efficiency, and maintaining customer confidence as businesses move into Q1 2026. Organisations that apply structured forecasting, strong visibility, and clear stock strategies are better prepared for market and supply-chain pressures. Corless Logistics Group supports these needs with tailored logistics services, including warehousing, transport, inventory coordination, and end-to-end operational management for high-demand periods.

Contact us today to learn how we can strengthen your operations and support your goals for Q1 2026 and beyond.

Related Blog Articles:

Supply Chain Consulting: How Corless Logistics Fixes Gaps in Your Inventory Workflow

Logistics Solutions Built for Australian Businesses — Start Shipping Smarter