Corless Logistics Group provides a practical guide on reverse logistics for retailers, streamlining returns, refurbishment, and customer satisfaction.

Customer expectations continue to rise, with seamless purchasing and transparent return options now considered essential. Reverse logistics for retailers provides a structured approach to managing returns, refurbishment, and resale while protecting profit margins and building trust. Without it, retailers face mounting costs, reduced customer satisfaction, and missed sustainability goals.

What is Reverse Logistics?

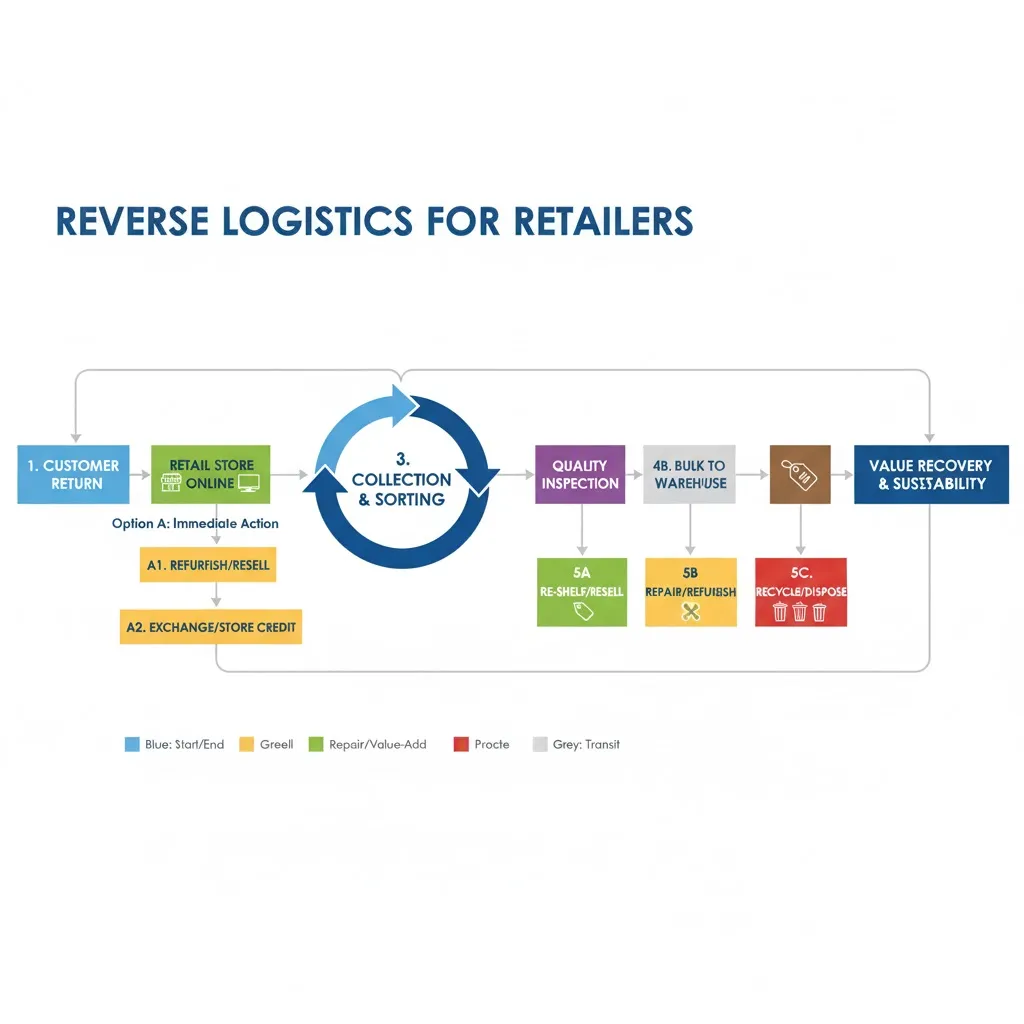

Reverse logistics refers to the process of moving goods from customers back through the supply chain for returns, refurbishment, resale, or recycling. Unlike traditional logistics, which focuses on getting products into consumers’ hands, reverse logistics ensures those same products can be reintegrated into the retailer’s operations with minimal waste.

The process involves managing return authorisations, transport, sorting, and refurbishment to determine the most cost-effective outcome for each product. For retailers, reverse logistics goes beyond handling unwanted items to creating a long-term strategy that enhances customer satisfaction and supports sustainability.

Why Returns & Refurbishment Matter for Retailers

The growth of online shopping has led to higher return volumes, with customers expecting simple and cost-free processes. Efficient management of returns and refurbishment is vital, as each return impacts margins through handling, restocking, and resale costs. Retailers that streamline these processes not only improve customer loyalty but also demonstrate a strong commitment to sustainability.

Common Challenges in Retail Reverse Logistics

While reverse logistics creates opportunities for cost recovery and customer retention, it also presents several challenges. Retailers often face issues such as:

• Inefficient returns management systems.

• Hidden costs: restocking, handling, transportation, and disposal.

• Fraudulent returns and abuse.

• Lack of visibility in the returns process.

These challenges can erode profit margins and reduce customer satisfaction if not properly managed. By recognising these barriers early, retailers can develop strategies that streamline processes, reduce unnecessary costs, and improve operational transparency.

Technology & Automation in Reverse Logistics

Technology and automation are increasingly essential in building scalable, efficient reverse logistics processes. Retailers that invest in the right systems can gain better visibility, improve processing speed, and reduce manual errors.

• Warehouse & Transport Management Systems – Advanced warehouse management systems (WMS) and transport management systems (TMS) allow retailers to track returns from the moment they are initiated. These tools automate key functions, such as restocking or routing items for refurbishment, reducing delays and improving cost efficiency.

• Data & Predictive Analytics – Analytics tools help retailers identify trends in product returns, which can highlight quality issues, customer behaviour patterns, or fraudulent activity. By forecasting returns more accurately, retailers can better manage inventory levels and refurbishment capacity.

• Tracking & Traceability Technologies – Technologies such as RFID and barcode scanning provide greater visibility across the supply chain. This ensures that products are quickly identified, sorted, and redirected to the appropriate channel—whether resale, refurbishment, or recycling.

Optimising Reverse Logistics for Retailers with Corless Logistics Group

Reverse logistics for retailers is now a core element of retail strategy, helping businesses recover costs, strengthen their brand, and build customer loyalty. By applying structured frameworks and automation, returns and refurbishment can shift from a challenge to a value-adding opportunity. At Corless Logistics Group, we deliver tailored solutions that streamline reverse logistics, ensure efficient returns management, and support sustainable outcomes.

Contact us to unlock the full potential of reverse logistics and deliver the customer experience your business needs to stay competitive.

Related Blog Articles:

Logistics Solutions Built for Australian Businesses — Start Shipping Smarter

Wholesale Logistics Services: Your Path to Retail Supply Chain Optimisation